Full-Service for the Datacenter Market

Service has been a core offering from Ash Battery since our inception in 1954. The products and technologies have changed, but the excellent customer service and quality standards have remained a top priority. Staffed with experienced Telcordia-trained technicians, our service department is equipped to handle a range of power systems services.

Whether you need a single battery replaced or a completely new battery string installed, Ash Battery can handle your unique power systems maintenance. Our experienced, Telcordia-trained technicians have been serving the upper Midwest since 1968. We can take care of your battery replacements from beginning to end, including removal and disposal of spent batteries. Our dedicated service team will work around your schedule to maintain zero downtime and keep your backup power facilities running smoothly.

For quotes and availability, please don’t hesitate to contact us.

There is no more effective means of protecting UPS equipment and backup power systems from failure than regularly scheduled preventative maintenance. No matter the size of your business, downtime carries a weighty price tag. Don’t suffer financial loss from preventable causes. Keep your UPS equipment running at optimum efficiency, both maximizing your power system’s capability and proactively protecting your revenue stream, with the assistance of Ash Battery’s experienced technical staff.

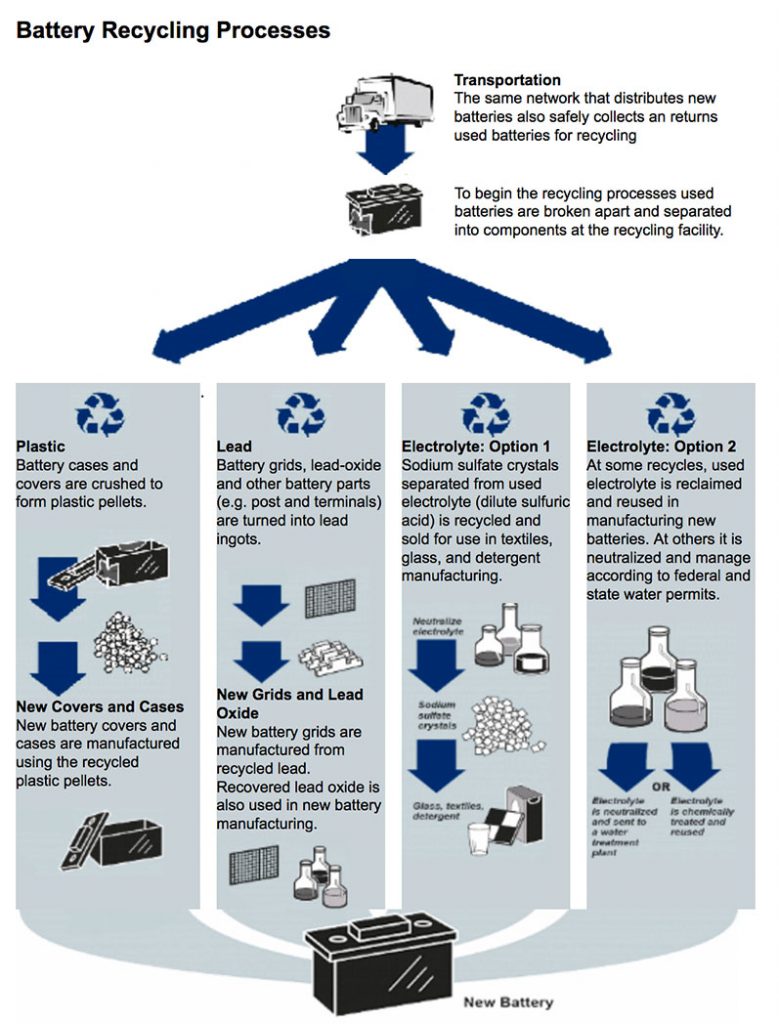

Ash Battery technicians are commercially licensed and certified to haul hazmat batteries and related materials. As an authorized hazmat transporter, we work in conjunction with local recycling facilities to ensure that proper disposal procedures are met.

As part of our service offerings, Ash Battery provides recycling certificates documenting that proper disposal procedures have been satisfied according to the Environmental Protection Agency’s rules and regulations. Ash Battery issues these certificates to our customers as sufficient evidence of consumption of spent lead acid batteries.

Ash Battery testing programs for stationary batteries and dc power systems meet or exceed the original equipment manufacturer’s (OEM) requirements and the recommended practices of IEEE Standards 450, 1106 and 1188 for vented lead acid, nickel cadmium and valve regulated lead acid (VRLA) respectively.

Our Performance Test of Battery Capacity (load discharge test) capabilities allow us to perform battery discharge tests on all vented lead acid, VRLA and nickel cadmium battery types of any ampere-hour capacity. Our knowledge of capacity testing and use of state of the art data acquisition equipment allows us to accurately evaluate the capability of the entire battery string along with each cell or multi-cell jar to deliver the manufacturer’s rated discharge current for a given duration. The capacity test also allows us to determine the state of battery aging.

- Acceptance Test of New Stationary Batteries

- Certification, Start-Up, Test of Stationary Battery, Rectifiers and DC Power Plants

- Monthly, Quarterly, Annual Inspection and Testing

- VRLA Ohmic Test

- Performance Test of Battery Capacity

– 24 V and 48 V Telecommunications Batteries

– 125 V and 250 V Switchgear and Control Batteries

– 120 V/240 V/360 V/480 V UPS Batteries - DC Ground Test

- Battery Charger/Rectifier Inspection and Testing

Ash Battery offers these training services:

- Product Training

- DC Power System Maintenance & Testing Training

- DC Power System Design Training

- DC Ground Fault Location Training

- Safety & OSHA Compliance Training

- Personnel Qualifications For Installation & Maintenance of Stationary Batteries In Accordance With IEEE STD. 1657

Ash Battery offers these consultation services:

- Battery and Battery Charger/Rectifier Sizing

- DC Power System Iinitial Design, Specification, and Equipment Selection

- Root Cause Failure Investigations

- Maintenance and Testing Program Development

- Energy Storage System, Advanced Battery Technology Evaluations, and Reviews

- Stationary Battery Life Cycle and Cost Analysis

- System Performance and Test Data Evaluation

- Training Seminars